Soundproof gypsum fiberboard panel Vidiphonic SK 12.5/1200/2000 mm

Advantages

- Homogeneous

- High strength in both directions

- High density from 1100 to 1400 kg/m3

- Non-combustible A1 or A2-s1, d0

- Special systems

Technical Specifications

- Thickness: 12.5 mm

- Width: 1200 mm

- Length: 2000 mm

- Edge: SK

- Area: 2.4 m2

Storage

Panels should be stored horizontally on wooden pallets or battens, in dry rooms, protected from moisture.

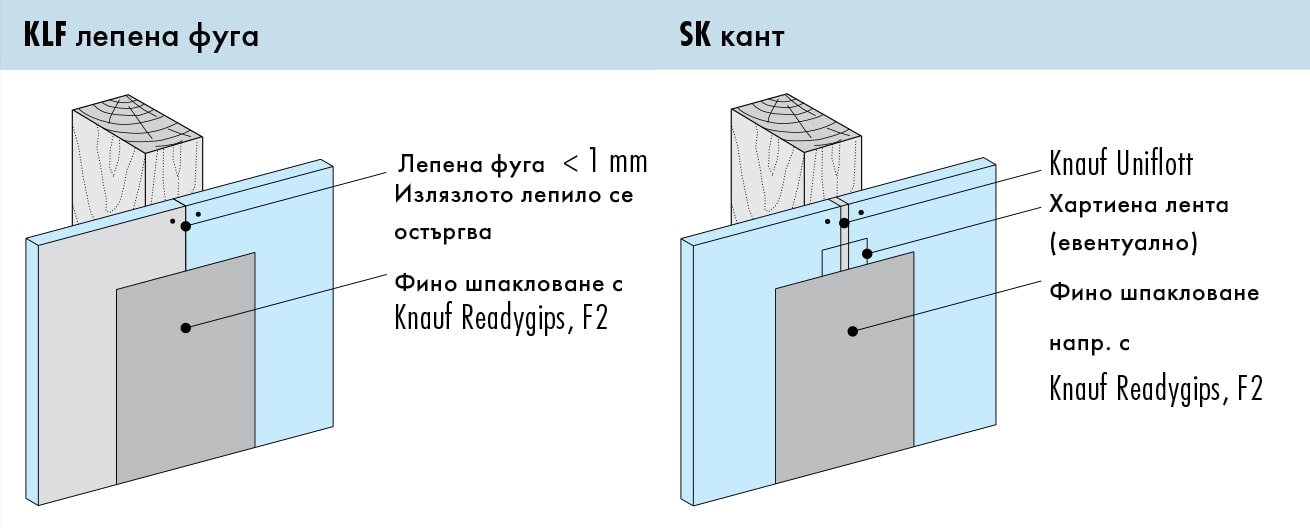

Edge Options

SK Edge - for bottom (invisible) layers of multilayer cladding - panel width 1200, 1250 mm

When installing the bottom cladding layer or below the installation plane, panels should be mounted tightly next to each other. The joints of the upper layer should remain open and be filled with Uniflott, along with paper tape.

SK Edge - open joint - panel width 1195, 1245 mm

Manual plastering with Knauf Uniflott and paper tape covers the joints. Panels are laid with a joint (joint width 5 - 7 mm), then Uniflott is used to fill the joint. Excess material is removed after about 40 minutes. The plaster material is applied with a trowel or wide spatula, followed by applying reinforcing tape.

SK Edge - glued joint - panel width 1195, 1245 mm

Knauf Vidiwall polyurethane adhesive is applied as a cord on the edge of the already installed Vidiwall panel. The next panel is placed on the supporting structure and pressed against the adhesive (joint width < 1 mm), the panel is secured with clamps or screws. Excess adhesive is removed with a spatula within 1 hour. When mounting Vidiwall panels with a glued joint directly on the base, there should be no adhesion of the panel to the base (e.g., OSB panel).

Cutting

Panels with a thickness of up to 12.5 mm can be cut with a utility knife and broken along the edge of the setup. The broken edge can be leveled with a hand plane and cleaned of dust, especially when laying with an open or glued joint. Clean edges can be achieved with a handsaw or circular saw (use aspiration).

Fastening Methods

Appropriate means should be used for panel installation, depending on the main supporting structure. Panels are fastened with screws, nails, or clamps. Fastening to wooden structures is done with nails and clamps (DIN 1052), galvanized or with another anti-corrosion coating. It is possible to fasten one panel to another in the case of double cladding. Panels are attached to a metal or wooden structure with rapid screws (DIN 1052/EN 14566).